10 Operations Management Decisions

Operations management involves making strategic decisions to ensure that a business runs efficiently and effectively. There are 10 key decisions that operations managers must make in order to optimize processes and achieve organizational goals:

- Design of Goods and Services: This decision involves determining what products or services will be offered to customers and how they will be designed to meet customer needs.

- Quality Management: Ensuring that products or services meet quality standards is crucial for customer satisfaction and retention.

- Process and Capacity Design: Operations managers must design processes and determine capacity levels to ensure that production meets demand efficiently.

- Location Strategy: Choosing the right location for facilities can impact costs, customer accessibility, and overall operational efficiency.

- Layout Design: The layout of facilities can impact workflow, productivity, and employee satisfaction.

- Human Resources: Hiring, training, and managing employees is essential for ensuring a skilled workforce that can meet operational goals.

- Supply Chain Management: Managing the flow of materials, information, and finances across the supply chain is critical for efficient operations.

- Scheduling: Determining production schedules, employee shifts, and resource allocation is key to meeting demand while minimizing costs.

- Maintenance: Regular maintenance of equipment and facilities is necessary to prevent breakdowns and ensure smooth operations.

- Inventory Management: Managing inventory levels to balance supply with demand is crucial for controlling costs while meeting customer needs.

By making informed decisions in these 10 key areas of operations management, businesses can improve efficiency, reduce costs, enhance quality, and ultimately achieve greater success in today’s competitive marketplace.

Mastering Operations Management: 5 Key Tips for Optimal Decision-Making

- Design of goods and services

- Quality management

- Process and capacity design

- Location strategy

- Supply chain management

Design of goods and services

The decision on the design of goods and services plays a crucial role in operations management. It involves determining what products or services will be offered to customers and how they will be designed to meet customer needs effectively. By focusing on this decision, businesses can tailor their offerings to align with customer preferences, differentiate themselves from competitors, and ultimately drive customer satisfaction and loyalty. A well-thought-out design of goods and services can set the foundation for successful operations and contribute significantly to the overall success of a business.

Quality management

Quality management is a crucial aspect of operations management that focuses on ensuring products or services meet established quality standards. By implementing effective quality management practices, businesses can enhance customer satisfaction, build brand reputation, and increase operational efficiency. This involves monitoring and improving processes to consistently deliver high-quality products or services that meet customer expectations. Quality management also plays a key role in reducing waste, minimizing defects, and ultimately driving long-term success for the organization.

Process and capacity design

Process and capacity design is a critical decision in operations management that involves designing efficient processes and determining the optimal capacity levels to meet demand effectively. By carefully planning and optimizing processes, businesses can streamline production, reduce bottlenecks, and improve overall operational efficiency. Capacity design ensures that resources are allocated appropriately to meet customer needs without overburdening the system. Making informed decisions in process and capacity design can lead to cost savings, improved productivity, and enhanced customer satisfaction, ultimately contributing to the success of the organization.

Location strategy

Location strategy is a critical decision in operations management that can significantly impact a business’s success. Choosing the right location for facilities can affect factors such as transportation costs, accessibility to customers and suppliers, labor availability, and regulatory requirements. By strategically selecting a location that aligns with the company’s objectives and operational needs, businesses can optimize their operations, reduce costs, and improve overall efficiency. A well-planned location strategy can give a competitive advantage and contribute to long-term success in the market.

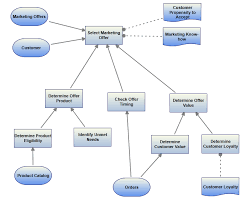

Supply chain management

Supply chain management is a critical aspect of operations management that involves overseeing the flow of materials, information, and finances from suppliers to manufacturers to retailers and ultimately to customers. Effective supply chain management ensures that products are delivered to the right place, at the right time, and in the right quantity. By optimizing supply chain processes, businesses can reduce costs, improve efficiency, enhance customer satisfaction, and gain a competitive edge in the marketplace. It involves strategic decision-making regarding sourcing, procurement, logistics, inventory management, and collaboration with partners to create a seamless flow of goods and services throughout the entire supply chain.